Exploring the World of Concrete Dyes: Adding Color to Your Concrete Surfaces

Concrete dyes have gained popularity for their ability to transform plain concrete into vibrant, customized surfaces. Whether for residential, commercial, or industrial applications, concrete dyes offer versatility, durability, and a unique aesthetic. In this blog, we’ll explore the types of concrete dyes, how they work, their benefits, and tips for using them.

1. What Are Concrete Dyes?

Concrete dyes are colorants applied to concrete surfaces to create rich, dynamic colors. Unlike stains that chemically react with concrete, dyes penetrate the surface for a more immediate and intense color effect.

Dyes are usually available in water-based or solvent-based formulations, each with different application and maintenance needs.

2. Types of Concrete Dyes

Water-Based Dyes: Known for lower odor and ease of application, these dyes provide a wide color range and are often UV-resistant.

Solvent-Based Dyes: Known for faster drying and more vibrant colors, but they may require protective measures due to fumes. These are typically used in indoor applications.

Powdered Dyes: Often mixed with water or solvents, powdered dyes offer flexibility in adjusting color intensity.

3. Benefits of Concrete Dyes

Color Variety: Available in an array of colors that allow for creative designs and effects.

Customizable: Dyes can be blended to create unique hues, enabling you to achieve exact color matches for design projects.

Fast Application and Immediate Results: Dyes are easy to apply and yield quick, uniform color, which is perfect for both new and existing concrete surfaces.

Durability: Dyes penetrate deeply into the concrete, offering lasting color even in high-traffic areas.

4. Application Tips for Concrete Dyes

Surface Preparation: Clean the surface thoroughly to ensure even dye penetration. Remove any dirt, oils, or sealers that could interfere with adhesion.

Test Colors First: Dyes can react differently based on the concrete’s age and porosity, so testing a small area can prevent unwanted surprises.

Application Tools: Sprayers, brushes, and rollers are all effective. Consider sprayers for even coverage and to avoid brush marks.

Sealing the Dye: Applying a sealant post-dyeing protects the color from fading due to UV exposure and wear, especially in outdoor areas.

5. Concrete Dye Uses and Popular Projects

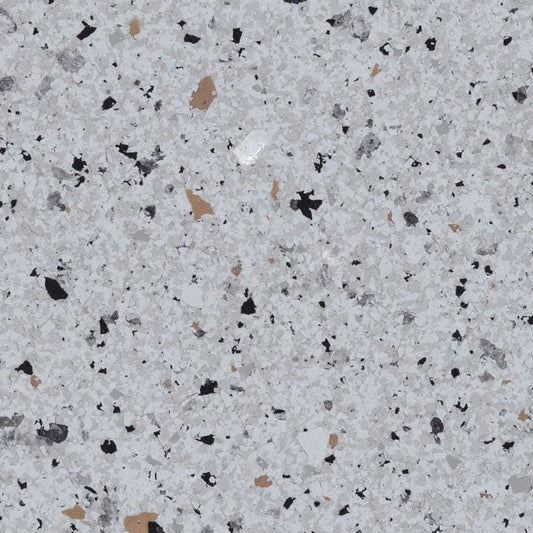

Residential Floors: Dyes can create elegant floors that mimic natural stone or polished marble.

Outdoor Patios and Walkways: With UV-resistant dyes and sealers, patios and walkways can withstand sun exposure while looking vibrant.

Commercial Spaces: Concrete dyes add sophistication to retail stores, showrooms, and offices.

6. Maintenance and Care

While concrete dyes are durable, applying a suitable sealant and regularly cleaning the surface will prolong the color’s lifespan.

Avoid harsh chemicals that may wear down the sealant or fade the dye. Stick to mild soap and water for regular cleaning.

7. Choosing the Right Dye for Your Project

Consider the Location: For outdoor projects, UV-stable dyes are essential to prevent fading.

Evaluate the Look You Want: Water-based dyes often offer more subdued hues, while solvent-based ones provide vivid, intense colors.

Project Size and Complexity: Large areas benefit from dyes that are easier to apply and that dry quickly.

Concrete dyes are a fantastic way to add color and life to concrete projects, enhancing the beauty and value of spaces. By choosing the right type, preparing the surface, and applying proper maintenance, you can enjoy beautifully dyed concrete surfaces that make a lasting impression