Why Polyaspartic Coatings Are Redefining Surface Protection: Insights from Valence Supply

At Valence Supply, we don’t just provide products—we offer long-term performance solutions for professionals and contractors who expect more. One of the biggest breakthroughs in the protective coatings industry today is polyaspartic coatings, and we’re here to tell you why they’re rewriting the rulebook on durability, speed, and aesthetics.

Polyaspartic: More Than Just an Epoxy Upgrade

For years, epoxy ruled the floor coating space. But as we’ve worked closely with flooring contractors, warehouse managers, and garage renovation teams, one message has become clear—the need for faster turnaround times without sacrificing performance is non-negotiable. That’s exactly where polyaspartic coatings shine.

Originally developed for high-performance automotive and industrial uses, polyaspartic technology has evolved into a game-changer for commercial and residential applications alike. It outperforms traditional coatings in chemical resistance, UV stability, and cure time—a triple threat that allows our clients to deliver better results in less time.

Why We Stand Behind Polyaspartic at Valence Supply

We’ve curated our product line based on what works best in the real world—not just in a lab. Here’s why polyaspartic coatings are front and center in our offerings:

1. Rapid Return-to-Service

Most coatings require downtime that stalls operations. Our polyaspartic systems cure in hours, not days, which means your clients can walk, drive, or work on their surfaces the same day. In fast-paced environments like auto shops or manufacturing facilities, that’s a major win.

2. Cold Weather Application

Unlike many coatings that become finicky in the cold, polyaspartic thrives in low temperatures. This makes it ideal for year-round projects—no waiting on the weather.

3. Superior Clarity and Gloss Retention

Whether it's a high-end retail showroom or a garage that doubles as a man cave, aesthetics matter. Polyaspartic coatings deliver long-lasting gloss and clarity that don’t yellow over time, even under UV exposure.

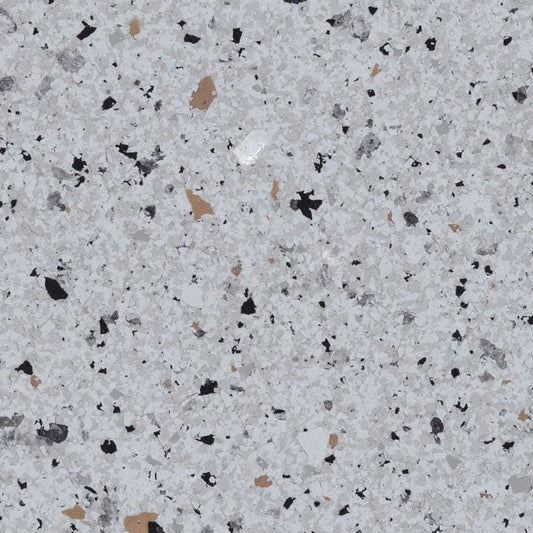

4. Customized Systems for Demanding Projects

We’ve worked with clients who needed coatings for aircraft hangars, commercial kitchens, even breweries—each with unique chemical and impact resistance needs. Our polyaspartic systems can be tailored with anti-slip additives, color chips, or industrial topcoats depending on your use case.

Common Misconceptions—and the Truth We Share with Our Clients

We frequently get questions like: “Isn’t polyaspartic too expensive?” Or “Can it really bond well to concrete?”

Here’s our take—cost per gallon doesn’t reflect total project value. When you factor in reduced labor time, minimized callbacks, and longer life cycles, polyaspartic is a smarter investment. Plus, with the right prep (and we carry every tool for that), adhesion is excellent—no peeling nightmares here.

Supporting Your Projects with More Than Just Product

At Valence Supply, we don’t drop a bucket of coating on your doorstep and disappear. We support you with detailed product guides, hands-on training, and real-world usage tips that save time and prevent costly mistakes.

We’ve helped hundreds of contractors transition to polyaspartic systems with ease. Whether you’re coating 500 square feet or 50,000, our team is here to make sure you get it done right.

Let’s Upgrade What Your Surfaces Can Do

Polyaspartic coatings represent the future of protective finishes—and we’re proud to lead that future with the right products, guidance, and technical expertise. When you partner with Valence Supply, you’re not just getting a better coating. You’re getting the support of a team that understands what it takes to elevate your results.